Air Poppets

PRODUCT INFORMATION

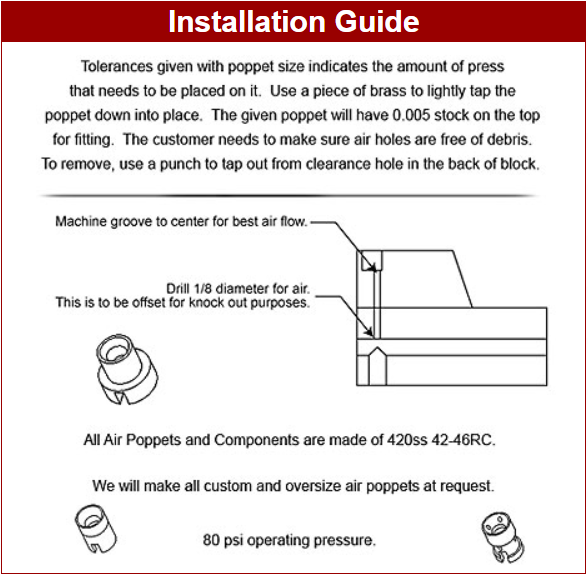

Fisher Tool & Design is well known for their air poppets. The air poppets are designed to break the vacuum created during injection molding. They are built to provide long life using all stainless steel materials and are heat treated to 44-46 Rc.

If you would like to place an order for air poppets, please email us at poppetsales@fishertool.net

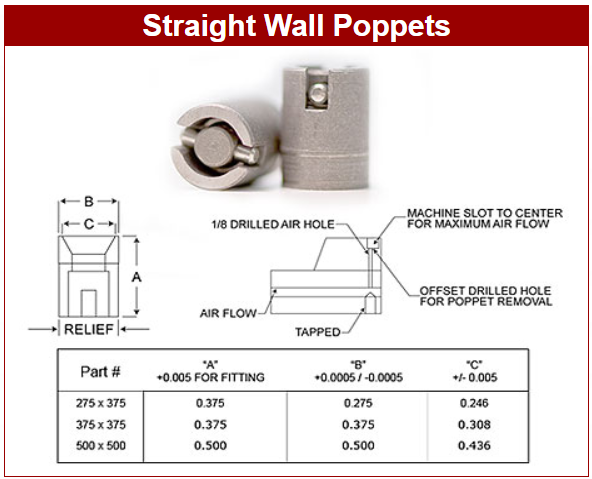

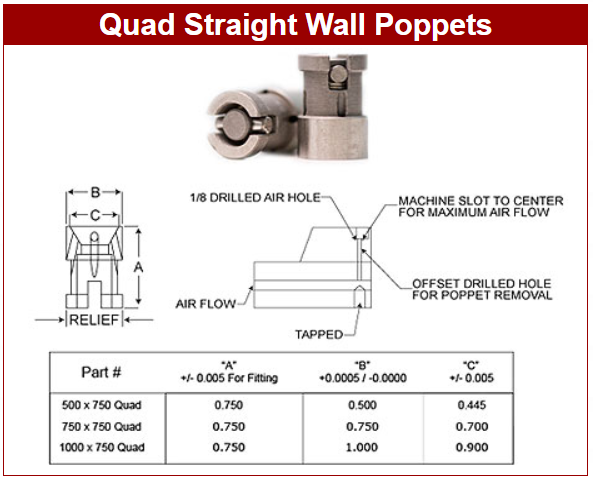

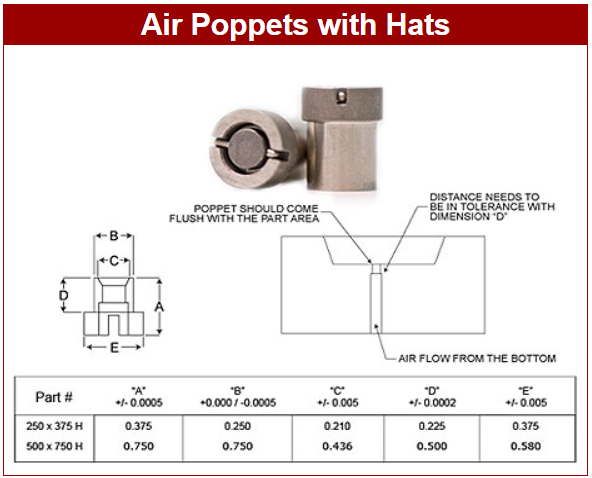

The following charts contain our standard size air poppets and their specs.

The straight wall air poppets are press fit into a counter bore that is machined into the molding surface. These air poppets have .005″ on the overall length to allow match grinding to the molding surface.

The Air Poppets with hats, signified with an “H” on the end of the part number, are designed to be installed from the backside of cavities into a slip fit hole. We also have oversized air poppets on hand and can design and build special sized air poppets.

Please feel free to contact us with any questions regarding our air poppets or any installation advice.

OFFICE LINE

812.867.8350

WORKING HOURS

6:00am – 4:00pm CST

OFFICE LINE

1.812.867.8350

WORKING HOURS